TL 185-630mm² 22-34.5mm Uhlobo lwepleyiti yoxinzelelo lwe-T-izihlanganisi zomqhubi omnye wohlobo lwebholithi

Ingcaciso yeMveliso

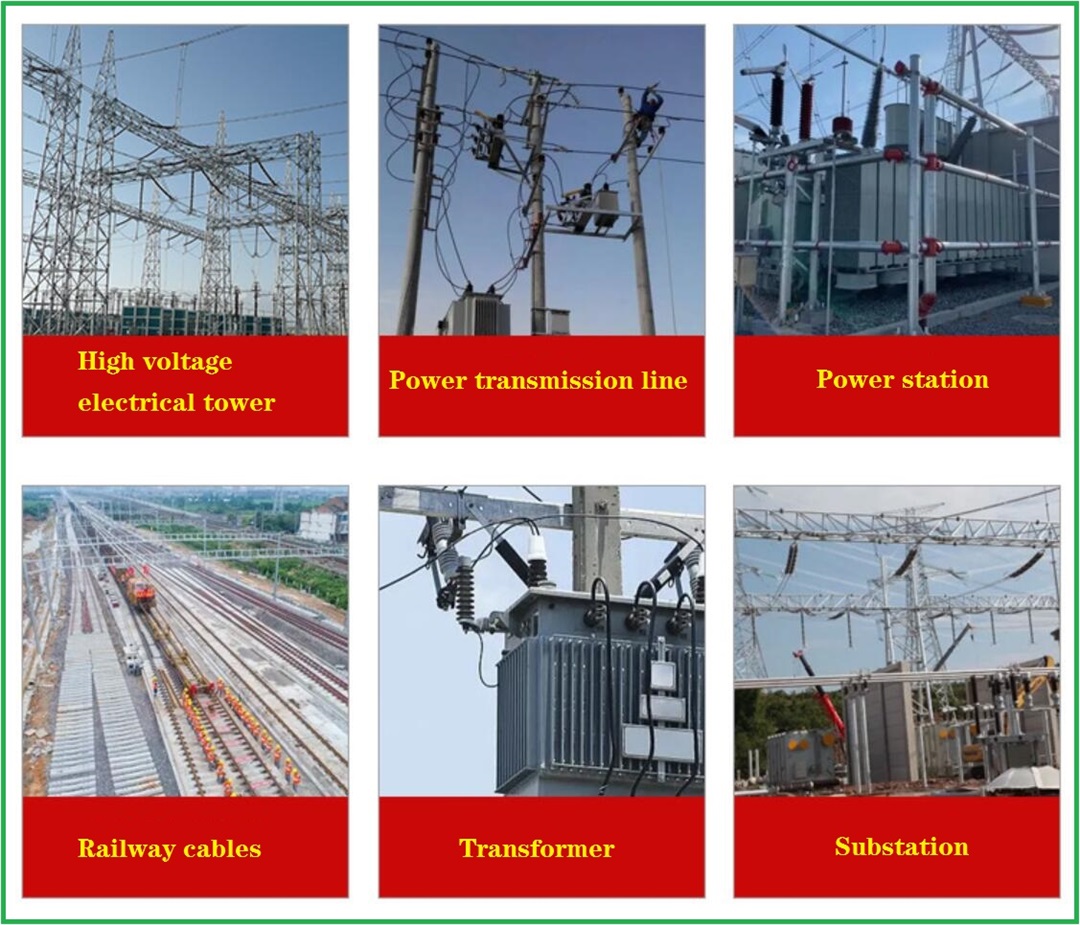

I-T-clamp ibhekisela kwi-hardware esetyenziselwa ukudibanisa umqhubi kunye nomgca wesebe ukuhambisa umthwalo wombane.Umgca wokuhanjiswa kwamandla aphezulu yinxalenye ebalulekileyo yegridi yamandla, edibanisa izikhululo kunye nokuhambisa amandla.Kuyilo lwemigca yothumelo, sinokubona indlela yokudibanisa yomgca we-T-uxhumano.Imigca yoqhagamshelo lwe-T yimizila emibini enamanqanaba ahlukeneyo esithuba adityaniswe yisiphaluka esifutshane kwi-intersection yezinga elifanayo lombane.Isitishi esingaphantsi A sibonelela ngombane kwizitishi ezingaphantsi B no-C ngaxeshanye.Iinzuzo kukuba utyalo-mali luyancitshiswa kwaye indawo yesikhululo sombane isetyenziswa kancinci.Le ndlela yokudibanisa omnye umgca ukusuka kumgca oyintloko ubizwa ngokucacileyo ngokuthi "T" imo yokudibanisa, Le ndawo ephumayo ibizwa ngokuba yi "T contact".

I-T-type clamp isetyenziselwa ikakhulu imigca yesekethe ephezulu okanye izitishi, ezikhokelela ezantsi kumasebe akhoyo kwibhasi ephambili ngendlela "T".Kukho iindidi ezimbini: uhlobo lwebholiti kunye nodidi loxinzelelo.Kubaqhubi becandelo elincinci, into ebizwa ngokuba yi-T-type connection ingasetyenziselwa kunye ne-parallel groove clamps okanye i-clamped elliptical splicing tubes.

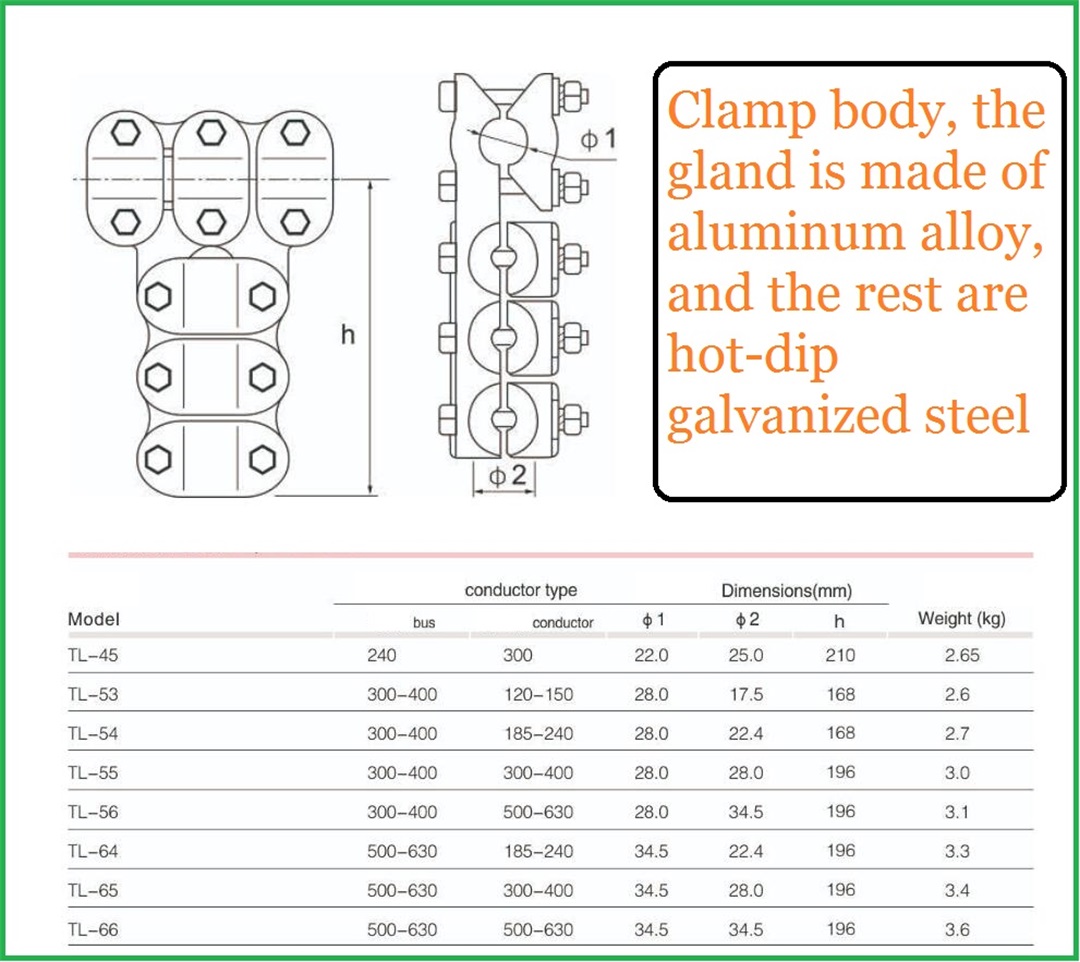

Uluhlu lwe-TL umqhubi omnye we-T-clamp luhlobo lwe-T-clamp esetyenziselwa ukudibanisa i-conductor yesebe kwi-trunk conductor, kubandakanywa: i-substrate ene-T-shaped, kunye ne-trunk groove kwindawo enqamlezayo, enemingxuma yocingo kwi-longitudinal part, i-lining linings. ibekwe eludongeni lwangaphakathi lwe-trunk groove kunye nomngxuma wesebe, kunye neentsimbi ezimbini zetsimbi zidibaniswe ngokupheleleyo, kwaye indawo ephezulu ye-longitudinal inxalenye ye-substrate ifakwe nge-screws yoxinzelelo lwe-conductor yesebe;Isigqubuthelo se-trunk slot sifakwa kunye ne-trunk slot, kwaye umphezulu wayo ongaphezulu ukrwelwe ngesikrufu soxinzelelo somqhubi owomileyo;Ikhava engaphezulu emile okwe-T ibotshwe ngesiseko esibunjwe ngu-T.Xa udibanisa, kuphela umsebenzi olula we-screws yokudibanisa iyadingeka, ogcina ixesha kunye nomsebenzi;Intambo yesebe kunye nocingo olomileyo lunxibelelana ngokusondeleyo kunye nentsimbi yentsimbi ngokusebenzisa i-screw compression, kwaye indawo yoqhagamshelwano inkulu, ngoko uxhulumaniso lukhuselekile kwaye luthembekile.

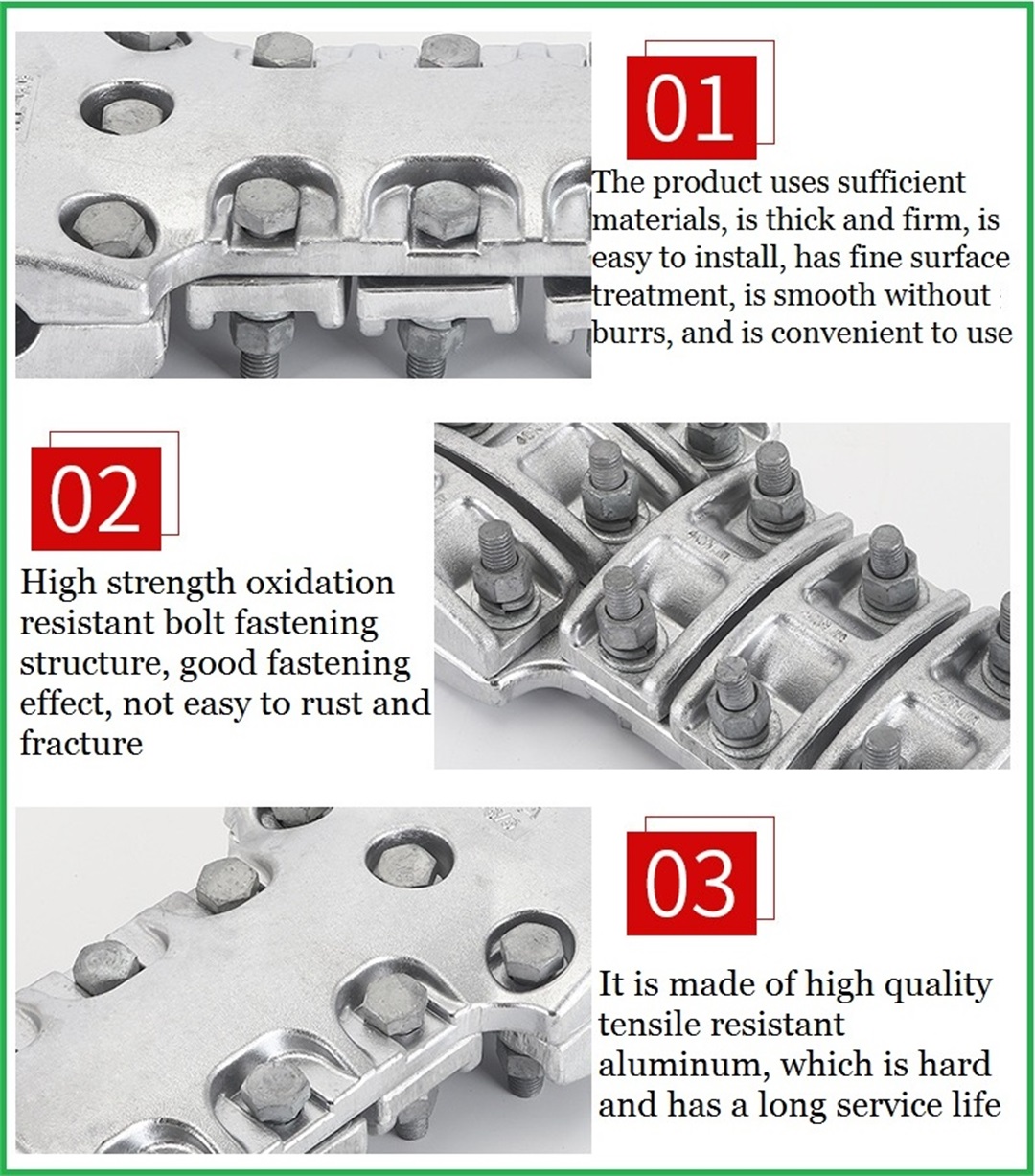

Iimpawu zemveliso kunye nemiyalelo yokusetyenziswa

Iimbonakalo:

a.Izinto zekliphu yocingo zifana ncakasana nezinto ezisongelweyo (intambo ephothiweyo), ngaloo ndlela iqinisekisa ukuxhathisa okuqinileyo kwe-corrosion.

b.Uyilo olukhethekileyo lwe-T-clamp lugwema ukulahleka okanye ukulimala kweebholiti, amantongomane, ama-washers kunye namanye amacandelo ngexesha lofakelo okanye ukusebenza, kwaye unokuthembeka okuphezulu ekusebenzeni.

c.Umgangatho wofakelo we-wire clamp awuchaphazeli kancinci kwizinto zomntu zabasebenzi bofakelo, umgangatho wofakelo uhambelana, kwaye inkqubo yokufakela ayiyi kulimaza ucingo.

d.Ufakelo lwekliphu yocingo kulula kwaye lukhawuleza, ngaphandle kwezixhobo, kwaye umntu omnye unokugqiba ngokukhawuleza ukufakela ngezandla ezingenanto kwisiza.

Imiyalelo yokusetyenziswa:

a.Khetha i-T-connector efanelekileyo yohlobo locingo olulandelayo.Izihlanganisi ze-T zeenkcukacha ezahlukeneyo azinakuthathelwa indawo.

b.Ikliphu yocingo yohlobo lwe-T yimveliso yexesha elinye, kwaye akufanele isetyenziswe ngokuphindaphindiweyo emva kokuthwala uxinzelelo olupheleleyo.

c.Le mveliso ifanelekile kuphela ukufakwa ngabachwephesha abaqeqeshiweyo.

d.Ngaphambi kokufaka i-T-clamp, ucingo kufuneka luhlanjululwe ngokucokisekileyo ukuze lususe i-oxide layer, kwaye igrisi ekhethekileyo yomqhubi kufuneka isetyenziswe kumphezulu wocingo.

e.Le mveliso sisixhobo esichanekileyo.Ukuze kuqinisekiswe ukufakela okuchanekileyo, kufuneka kugcinwe kwibhokisi yokupakisha ukukhusela ukungqubana okanye uxinzelelo olunzima ngexesha lokuphatha ukuphepha ukuguqulwa kocingo olujikiweyo ngaphambili.

f.Xa usebenza kwimigca ephilayo okanye kufutshane nayo, kufuneka kunikwe ingqwalasela eyodwa ukuthintela iingozi zokothuka kombane.

g.Kunconywa ukuba udibanise ibha yebhasi kunye ne-conductor ephantsi ukuze ufezekise ukusebenza kombane ngoqhagamshelo lwe-jumper, kunye ne-T-shaped bar yokudibanisa ithwala kuphela uxinzelelo.

Iinkcukacha zemveliso

Iimveliso shot real

Ikona yocweyo lwemveliso

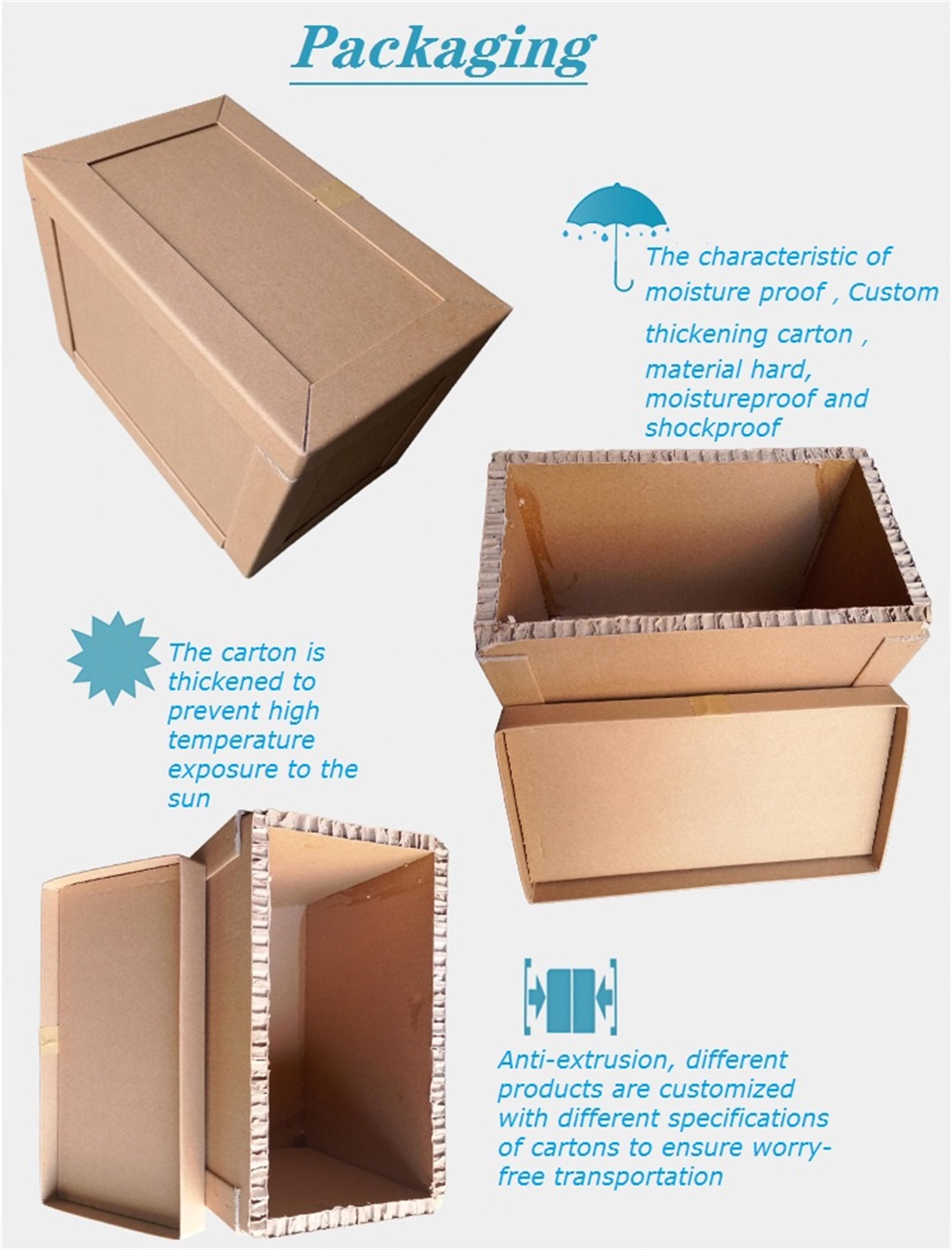

Ukupakishwa kwemveliso

Ityala lesicelo semveliso