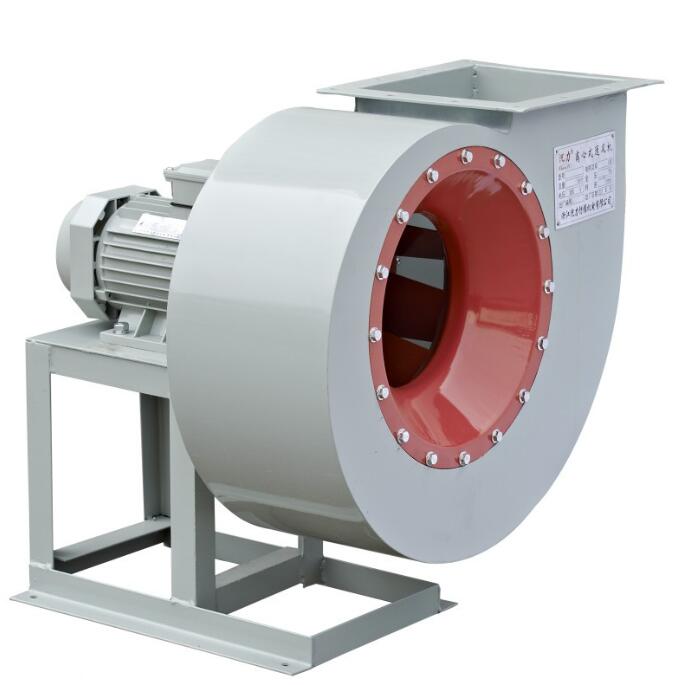

Explosion proof fan is used in places with flammable and explosive gases to avoid accidents caused by some flammable and explosive substances. Explosion proof fans are widely used for ventilation, dedusting and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings. Ventilation and ventilation of boilers and industrial furnaces; Cooling and ventilation of air conditioning equipment and household appliances; Drying and selecting grains; Inflation and propulsion of wind tunnel sources and hovercraft.

When the explosion-proof fan is used, it may encounter that the conveying gas contains flammable and explosive substances, dust, smoke or volatile substances. When the motor is short circuited, the circuit is faulty, and the friction between the fan impeller and its parts produces sparks, the transported substances or gases will be ignited and detonated, resulting in serious accidents. Therefore, the selection of explosion-proof fan is particularly important. Next, we will introduce some precautions for the selection of explosion-proof fan.

When selecting explosion-proof fan, pay attention to the following issues:

1. Determine the type of ventilator according to different purposes. For example, when delivering clean air, general ventilators can be selected for ventilation; Anticorrosive ventilators shall be used when transporting corrosive gases; Explosion proof ventilator or dust exhaust ventilator shall be selected when conveying flammable ventilator or dusty air.

2. Determine the fan model according to the required air volume, dust and selected fan type.

3. In order to facilitate the connection and installation of fans and system pipes, appropriate fan outlet direction and transmission mode shall be selected.

The explosion-proof fan model shall be selected according to the actual situation of the plant, and the fan model matching the original window size shall be selected as far as possible. The fan shall be kept at a certain distance from the wet curtain (installed on both sides of the gable of the plant as far as possible) to achieve good ventilation effect. Try to keep the exhaust side away from nearby buildings so as not to affect nearby residents.

From the perspective of fan, explosion-proof fan is driven by motor to generate wind power. The different functions of induced draft fan are determined by the components installed. The former is located at the rear end of the boiler, blowing air into the flue outside the boiler to produce negative pressure on the furnace and guide flue gas, so it is called induced draft fan; On the contrary, the latter is located at the front end of the boiler and blows air into the boiler, so it is called the blower.

When the explosion-proof fan operates normally, the noise cannot be eliminated. Research shows that as long as the wind speed exceeds 0.75 m/s, noise will be generated. Of course, the lower the wind speed, the less noise will be generated. Noise is harmful pollution. Doesn't it mean that the lower the noise is, the better? Low noise is good, but its economy must be taken into consideration. The lower the noise required, the higher the cost of the fan required. For every 10 dB reduction, the cost of the fan will double (empirical value, non-linear). The limit noise of most fans shall not be lower than 35dBA. Therefore, it is not necessary to pursue low noise when selecting fans, as long as it is within a reasonable and acceptable range.

Post time: Nov-12-2022