BJX 220/380V 10-400A Explosion proof anti-corrosion junction box

Product Description

The shell of the explosion-proof control box is made of aluminum alloy, and the surface is high-voltage electrostatic spray with beautiful appearance. The product protection grade is IP65. It is mainly suitable for IIA, IIB, IIC explosive gas environments. The main ammeter, switch, button, indicator light, thermal relay and other components in the box can be freely combined to achieve various functions.

Explosion-proof junction box is a special power distribution equipment used in various high-risk places. Compared with civilian junction boxes, it is a power distribution box with explosion-proof function that has been transformed from various explosion-proof.

Explosion-proof and anti-corrosion junction boxes are classified into: according to the functional material form: intrinsically safe explosion-proof junction box, aluminum alloy explosion-proof junction box, stainless steel explosion-proof junction box, steel explosion-proof junction box; according to the use structure, it is divided into: wall-mounted explosion-proof junction box And vertical explosion-proof junction box. Explosion-proof junction box series: The shell is made of impact-resistant glass fiber reinforced polyester material, and all metal parts are. The joint surface of the cover and the base is designed in a concave and convex shape, with a silicone rubber sealing structure to ensure the IP65 protection level. It is used as the branching and wiring for connecting various electrical equipment and instruments in the voltage 220V/380V line.

The junction box has three specifications: the built-in screw self-locking terminal has a specification of 2.5-3.5 square millimeters, and the lead wire is fixedly connected. Different types and specifications of cable glands meet different cable introductions: The plastic cable gland inlet (installation end) is metric thread, with anti-loosening clamping jaws inside, which has good mechanical characteristics. Unused cable entries can be sealed with blanking plugs for future retrofits and expansions for more convenient installations.

Model Description

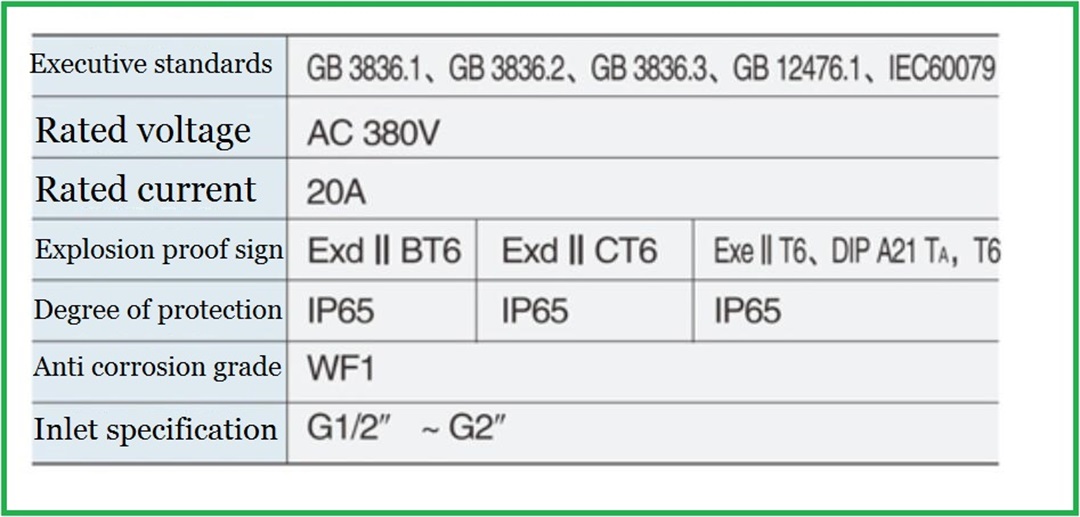

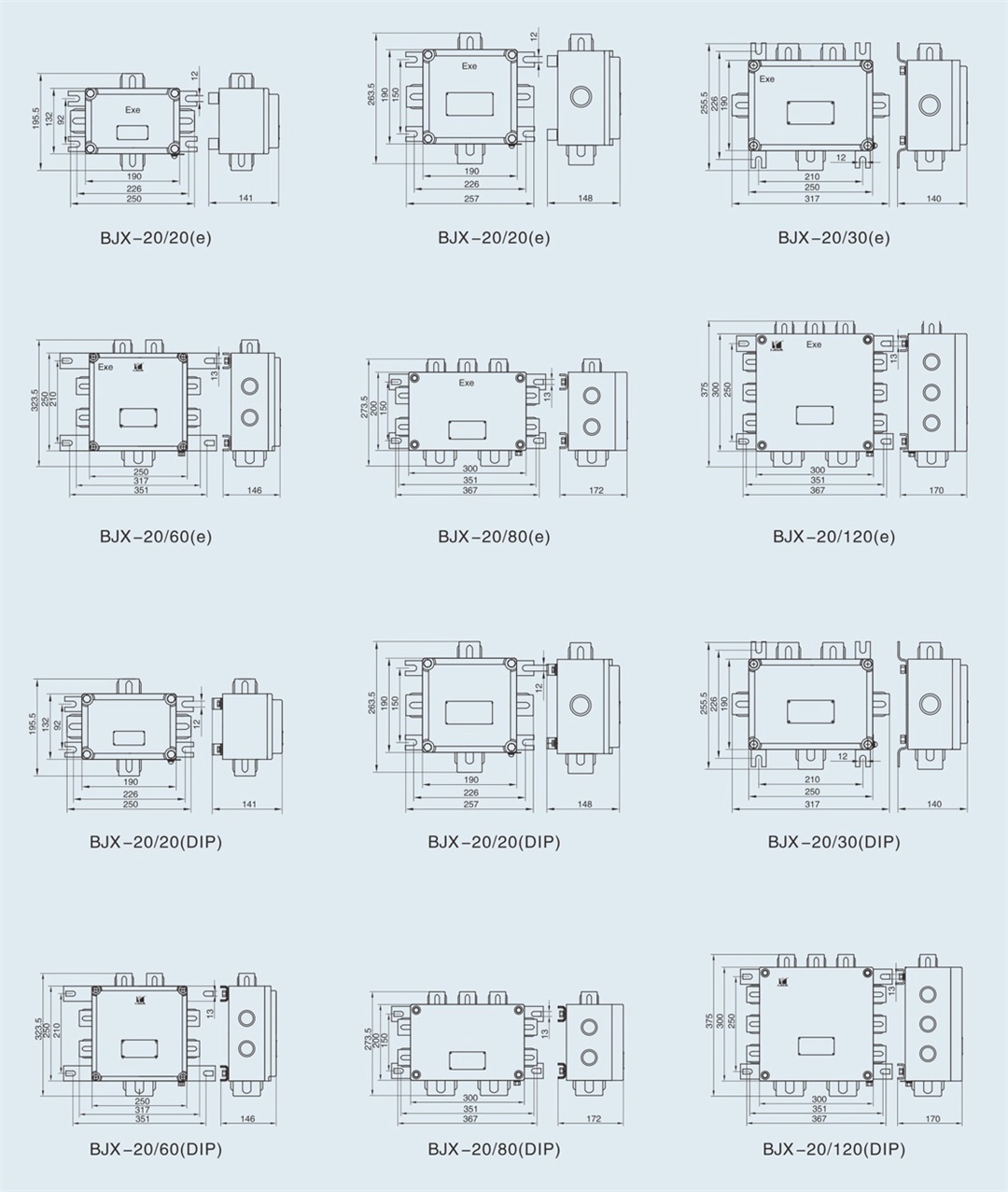

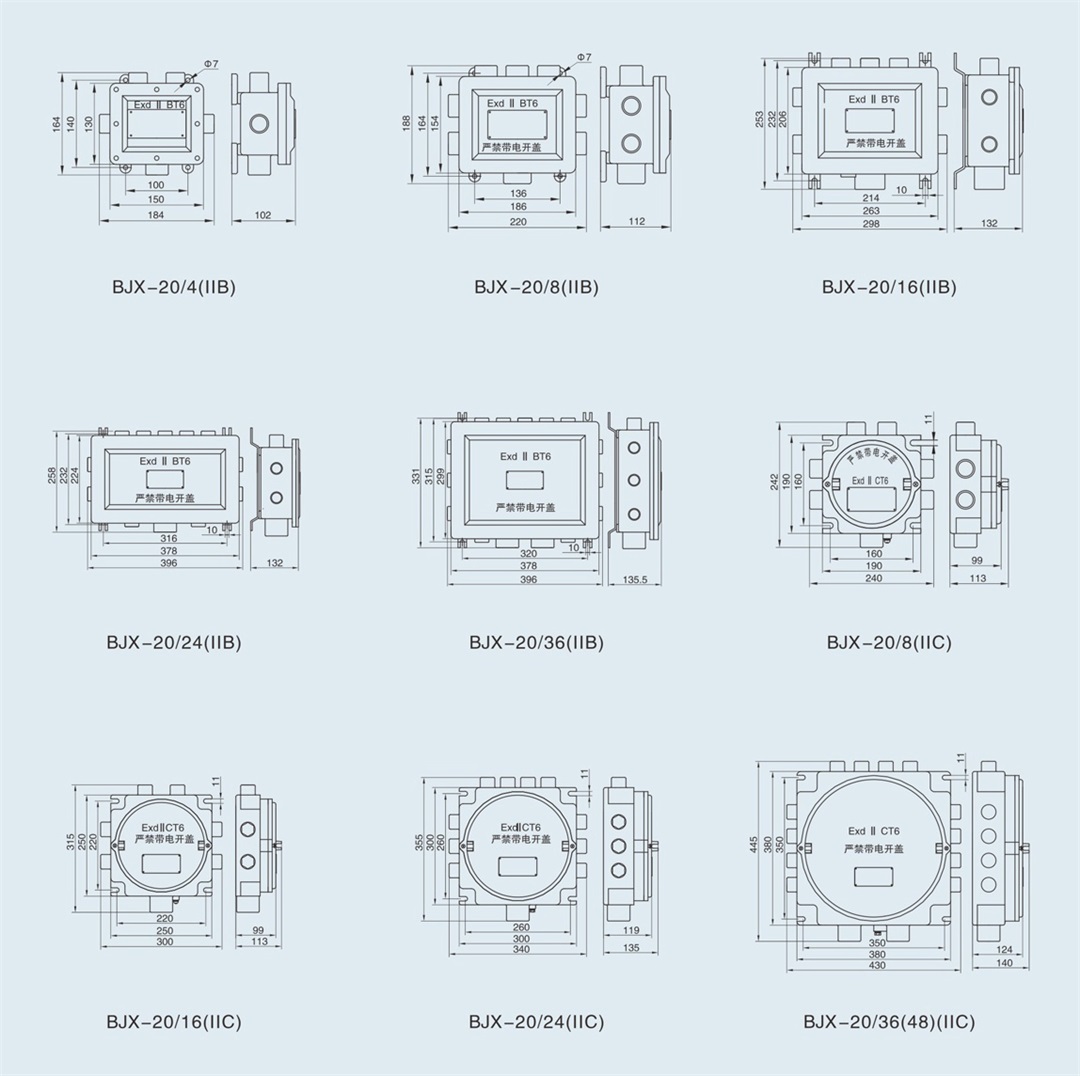

Technical parameters and structure dimensions

1. Explosion-proof mark: ExdIIBT4/T5/T6, ExeIIT4/T5/T6, DIP A20 TA, T4/T5/T6;

2. Rated voltage: AC220/380V, non-standard voltage: 12V/24V/36V/127V/660V;

Rated current: 10, 20, 32, 63, 100, 125, 200, 300, 400A

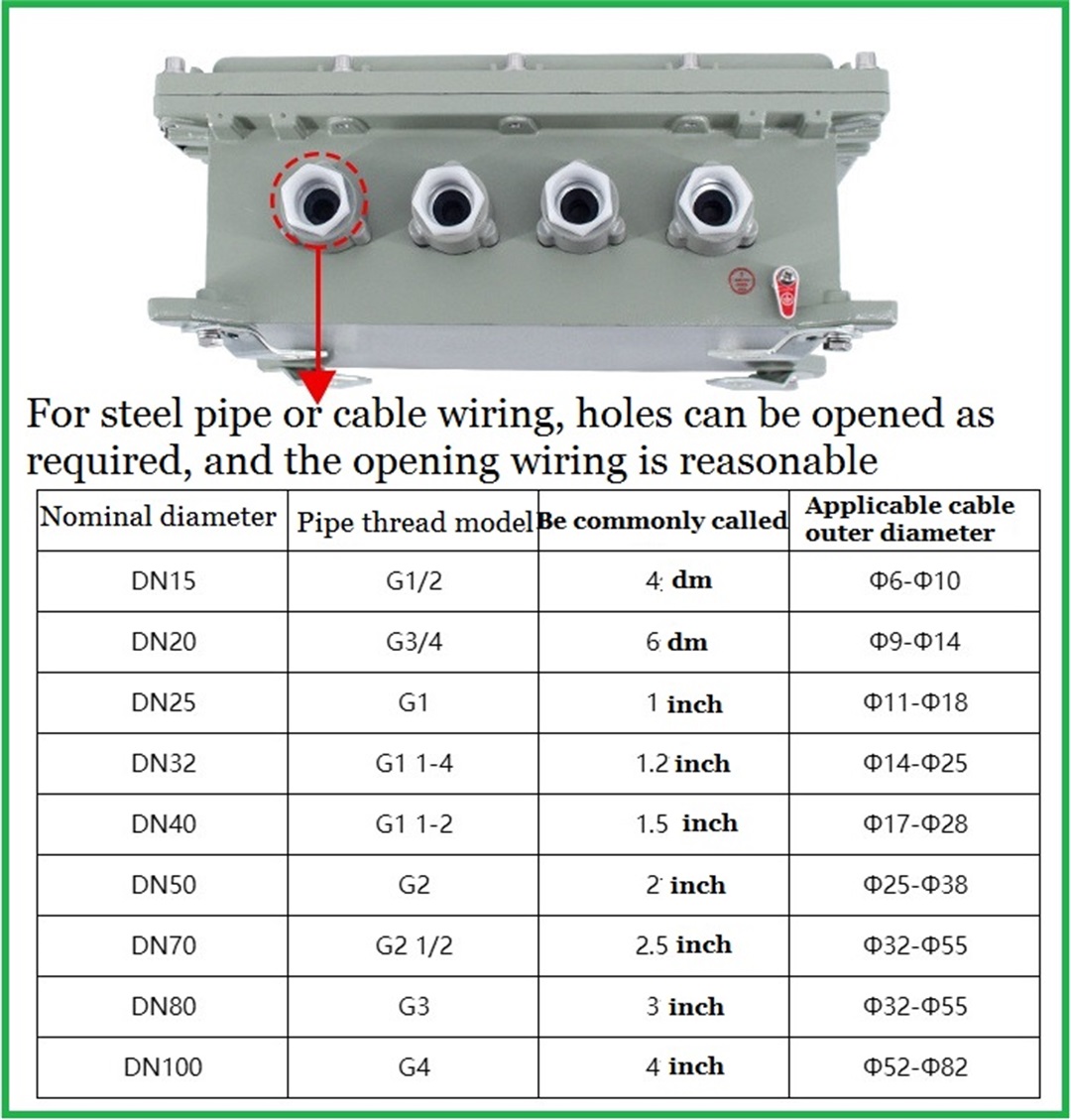

3. Number of incoming and outgoing wires: according to customer requirements 4. Thread specifications

: DN15-DN100/G1/2-G4 inches

Diameter 6mm-80mm; Lead wire specification: Diameter 6mm-80mm;

6. Protection class: IP54, IP55, IP65

7. Lead-in and lead-out direction: top in, top out, bottom in and bottom out (unlimited according to customer requirements)

8. Explosion-proof Mark: Exd II BT6/CT6

9. Anticorrosion grade: W, WF1

Product features and Operating environment

Features:

1. Various instruments, low-voltage electrical appliances, frequency converters, PLCs, soft starters, computer control systems, etc. can be installed in the explosion-proof control cabinet (box), which can realize various local operations and remote control.

2. The voltage level can be from 220V-1140VAC.

3. The explosion-proof control box generally has two types of structures: increased safety type and flameproof type. The outer casing adopts an increased safety box, and the built-in components adopt explosion-proof components or increased safety components; the outer casing adopts aluminum alloy die-casting, and the surface is high-voltage electrostatic spraying. The built-in components include buttons, control switches, instruments, etc., which are all explosion-proof components .

4. The explosion-proof structure shell is made of aluminum alloy casting, and the surface is high-voltage electrostatic spray. The internal components can be installed with explosion-proof components or ordinary low-voltage components such as relays, temperature controllers or various functional modules.

5. Installation method: hanging type, floor type

6, steel pipe or cable wiring

7. The internal components of the control box can be arranged according to the user's requirements, which can realize a variety of functions, and the control switch has a variety of functions to choose from. Indicator lights are also available in a variety of colors. Due to the variety of this product, please provide the circuit diagram when ordering. The

use environment:

1. The altitude should not exceed 2000m;

2. The ambient air temperature should not be higher than +60℃, not lower than -40℃; the relative air humidity should not be greater than 90% (+20 ℃);

3. The vertical installation inclination is not more than 5°;

4. There is no obvious shaking and strong shock and vibration;

5. There is no obvious damage to metal and insulation corrosive gases and vapors;

6. No dripping water and other where liquid penetrates

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case